1. From Tradition to Industry: The Lunar New Year Landscape and the Evolution of Gyoza

February. Across Asia, the “Lunar New Year” arrives, bringing a vibrant season where families gather together. An indispensable dish during this period is “Gyoza” (dumplings). There are various theories as to why gyoza came to be eaten at celebratory occasions. One common belief is that their half-moon shape resembles the silver currency once used in China; thus, they became popular as a lucky charm to wish for financial fortune, expressing the hope of being “blessed with money in the New Year.”

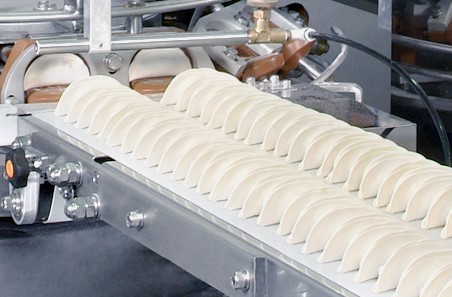

Traditionally, the sight of the whole family kneading dough for the skins and wrapping the filling on New Year’s Eve was a symbol of family harmony. However, modern China is experiencing a wave of intense urbanization. In urban areas, where nuclear families are becoming more common and double-income households are increasing, time-consuming “handmade” methods are rapidly being replaced by highly convenient, “high-quality frozen foods.”

These lifestyle changes in China, along with shifting dining trends centered in countries like Thailand and the Philippines, are prompting rapid growth in “dumplings” as a business not just in Asia, but worldwide. Within this trend lie many business opportunities born from automating manual labor for efficiency and scaling production without sacrificing taste.

2. Nepal’s “Momo” Dumplings Boom in India

Currently, India is one of the markets undergoing the most dynamic changes in the world. What is gaining immense popularity there now is the “Momo,” a dumpling originating from Tibet and Nepal. Wrapped with spicy fillings scented with cumin and coriander, this dish was originally a simple snack served at street stalls and small private shops.

A small food processor appeared that turned this “taste of the common people” into frozen momos using Japanese gyoza processing equipment. While they had absolute confidence in their own recipe, investing in Japanese equipment with limited capital was a major decision. However, their choice was “not to rely on local labor with low personnel costs, but to introduce highly reliable Japanese automated processing equipment.”

A representative from Toa Industry Co., Ltd., the company that received the order for the equipment, says: “By achieving consistency and high productivity—which are difficult to maintain with handmade methods—that small food manufacturer’s frozen momos grew into a popular brand in no time. Eventually, a massive local conglomerate took notice of their brand value and approached them with an offer for acquisition at a surprisingly high price.”

Following this success, Toa Industry received a flurry of inquiries from other Indian companies. Currently, a total of approximately 20 of the company’s machines are active across several firms within India. However, the production volume from about 20 machines can only supply a portion of the supermarkets. In a country with as many consumers as India, the representative says it is “like a drop in the ocean.”

This suggests that if one combines a unique recipe with Japanese food processing technology, there is ample room for success.

3. “GYOZA” Trends in North America, Europe, and Southeast Asia

The reason Japanese-style pan-fried dumplings began to permeate the West as “GYOZA” was primarily due to the global popularity of ramen that started in the 2000s. Japanese-style ramen shops opened one after another in New York, London, and Paris. There, the pan-fried dumplings served as an essential side dish for ramen established their own unique status as “GYOZA.” According to the representative, approximately five large-scale processing machines are currently being introduced annually to Europe, with a similar number to North America, for the production of frozen GYOZA.

Furthermore, demand for “GYOZA” is also high in Thailand, where a Japanese ramen chain operating locally has grown to a sales scale exceeding its headquarters in Japan. In its central kitchen, Japanese gyoza processing equipment is in full operation. Meanwhile, in privately owned ramen shops, space-saving tabletop gyoza machines are popular, significantly outperforming large machines in terms of units sold. In regions with a high affinity for Japanese food, such as the West and Southeast Asia, it is expected that new store openings by individual owners will continue, and demand for small-scale machines will further expand.

4. Why “Japanese Equipment” Determines Business Success or Failure

There are gyoza processing machines in the world sold at about one-fourth the price of Japanese ones. However, business owners who prioritize long-term profitability ultimately choose Japanese equipment. The reason lies not just in “specs,” but in “business stability.”

Preventing “Downtime,” the Invisible Loss

For example, what would happen if a production line producing 10,000 units per hour stopped for a day due to a breakdown? There is a risk of being unable to fulfill delivery contracts with major supermarkets or restaurant chains, resulting in penalties. That loss could easily exceed the price difference of the equipment. The high durability boasted by Japanese machines, along with accurate maintenance and support, brings the benefit of “peace of mind” to owners. Furthermore, when trouble occurs, they respond quickly via remote support using videos and photos. The parts supply is also stable, protecting reliability.

A Track Record of Customization and Joint Development

When developing a new gyoza, many owners want to customize their production equipment to provide uniqueness. In fact, when one global food manufacturer was developing a “premium frozen gyoza” for the Chinese market, they wanted to create gyoza with a complex wrapping style to project a sense of luxury. That food manufacturer spent several years and hundreds of millions of yen jointly developing a dedicated automated line with Toa Industry Co., Ltd. More than 50 of the successfully completed lines were introduced to factories in China, realizing mass production of high-quality premium gyoza.

The Balance for “Deliciousness” and “Productivity” of Dough

However, it is not always best to customize everything. Experienced Japanese engineers identify the balance between “deliciousness” and “business profitability” to propose the optimal compromise. For example, to make the ultimate delicious gyoza, one must use good wheat flour and fold high-hydration dough many times to form gluten. However, fully automating this causes costs and labor to skyrocket. Therefore, by taking a realistic approach—”pursuing the maximum deliciousness possible within the range of a standard automated line”—many companies have achieved success.

5. From “Craftsman’s Hands” to “Owner’s Time”

Toa Industry’s gyoza machines cost about 1.5 million yen for a small model and about 20 million yen for a large-scale automated machine. Here, a business owner must weigh the cost of introducing this equipment against the labor costs of hiring craftsmen. Certainly, in regions where labor costs are extremely low or at a stage where the business scale is still small, manual manufacturing may be more profitable.

However, for an owner who wants to scale their business, capital investment carries more meaning than a simple cost comparison. For example, a small machine has the capacity to mold over 1,000 gyoza per hour. The machine enables a single operator to perform the work of three to four craftsmen. If five hours spent making gyoza can be reduced to one hour, the remaining four hours can be allocated to store improvements or new menu development. For an individual owner, this is an investment in “buying time.”

Furthermore, if one can introduce large machines and mass-produce their own brand of frozen gyoza, it becomes possible to supply restaurant chains and supermarkets. Like the momo manufacturer in India, it may be possible to grow a brand rapidly from a small-scale start.

6. FOOMA JAPAN 2026: The “Switch for Transformation” for Your Business

Now, Japanese gyoza processing technology is triggering a business “shift” in various parts of the world. For example, one American user captured the “gluten-free” need driven by rising health consciousness, developed gyoza made with rice flour dough, and successfully expanded their business. In Malaysia, “Halal-compliant” frozen gyoza were developed. They have also expanded their base to Indonesia and are increasing exports to Middle Eastern countries.

Whether it is Italian ravioli or Russian pelmeni, dumplings are a food familiar to many countries in various forms. With a recipe born from free thinking—unconstrained by conventional types—and a single Japanese gyoza machine, you might be the one to change the standards of food.

From June 2 (Tuesday) to June 5 (Friday), 2026, one of the world’s largest comprehensive foods processing exhibitions, “FOOMA JAPAN 2026,” will be held at Tokyo Big Sight. The theme this time is “The Shift is On.” At the venue, a series of production lines will be gathered—not just gyoza machines, but everything from mincing machines that support filling preparation to vegetable cutters. Furthermore, the venue covers the latest manufacturing technologies supporting all kinds of Japanese food businesses, from ramen to the rapidly growing onigiri (rice balls), and from traditional Japanese cuisine to sweets.

Advanced automation that solves labor shortages, outstanding precision, and maintainability that meets long-term trust. All of these should serve as the “switch” that elevates your business to the next stage. Please experience that innovation firsthand by “seeing and touching” it. In Tokyo, the best partner to rewrite the future of your business awaits you.